Business Challenge

A fortune 500 telecom company had challenges to maintaining optimal inventory levels and determining when and how much quantity fresh stocks need to be ordered to fulfill new customer requirements and network upgrades. The network has 100s of different parts/SKUs and each part has a different consumption pattern based on demands and the kind of part. Stockout of certain parts and overstocking of some other parts resulted in unmet demands and inventory pile up. In addition, there were CAPEX constraints for any emergency orders.

Approach and Solution

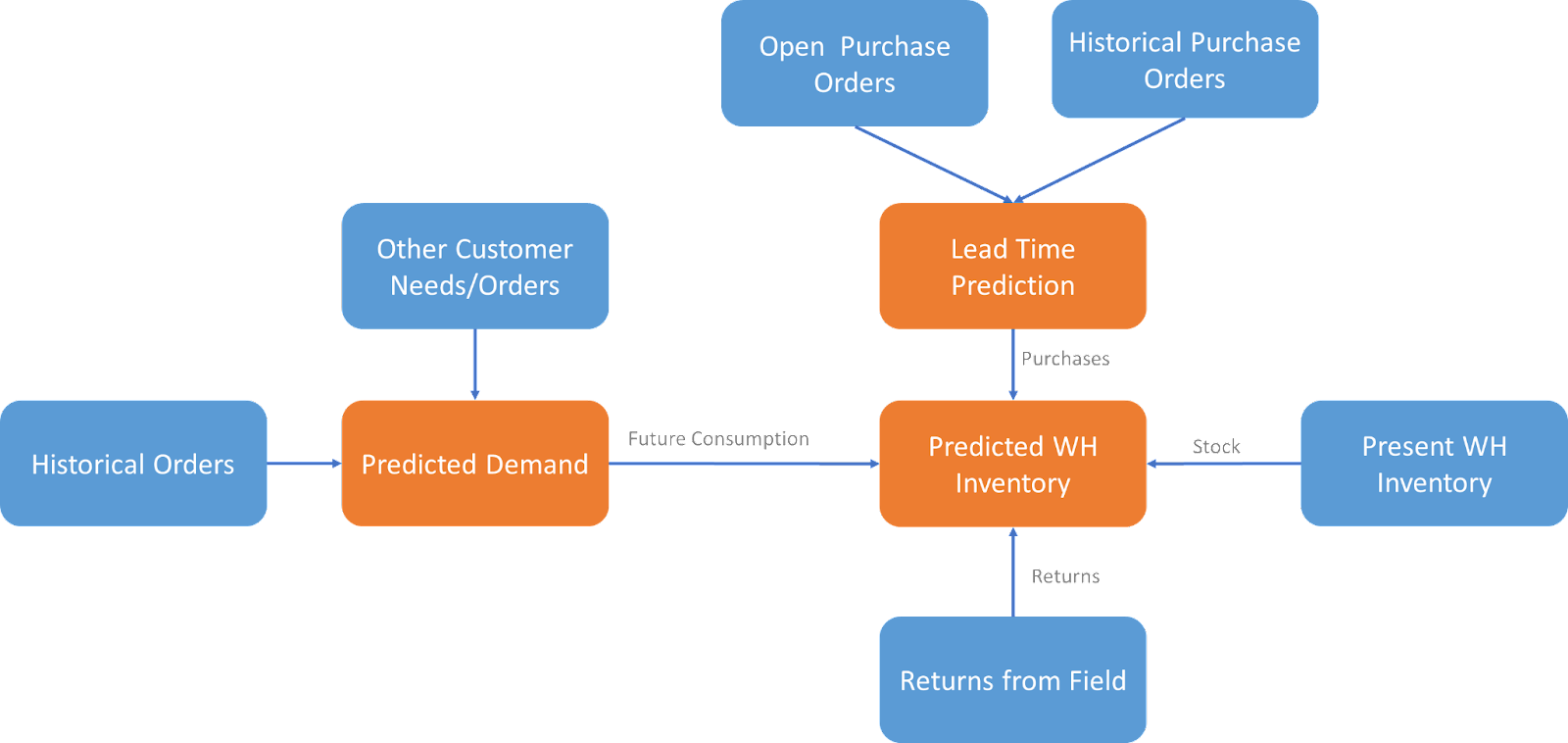

- The approach was to understand the demand of each part based on historical consumption patterns from various warehouses. An Additional factor that influenced the demand was any large new order which could be obtained in advance and was factored in. With this approach, each part/SKUs had a time series with its seasonality and trend. Some of them would not have seasonality or trend and some would have few data points to make accurate predictions. Taking into consideration, all these aspects a time series classification and prediction methodology were adopted to identify the right models for each part/SKU.

- The next step was to identify the lead times for orders based on historical data and then come up with reorder points and quantities. This takes into account safely stock calculation to avoid stockouts.

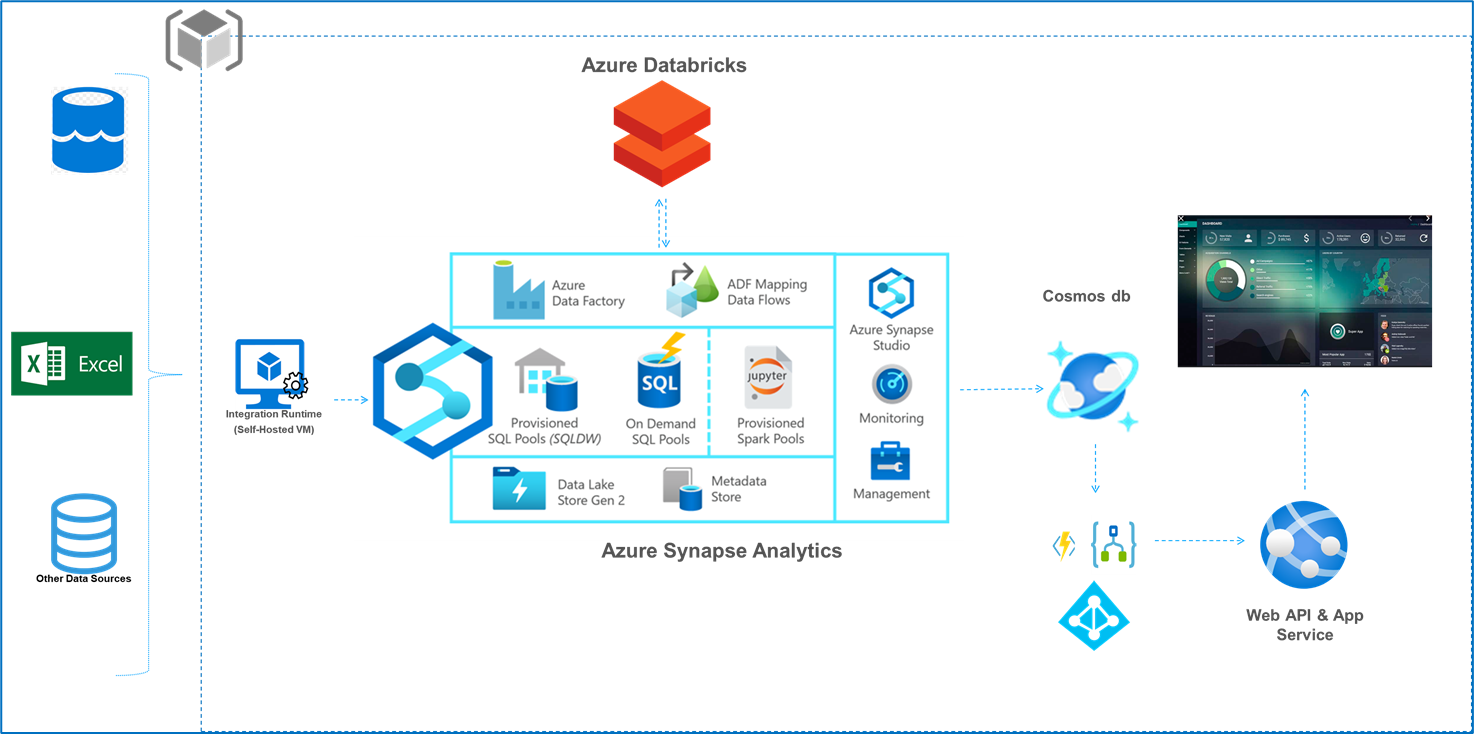

- The cloud platform chosen for building this application was Microsoft Azure. Data was ingested into Azure Synapse which helps in enterprise-level data analytics and data warehousing. Data preprocessing, model training, and prediction were done on Azure Databricks which is a Spark-based big data analytics service designed for data science and data engineering.

- The application was built out with the AI/ML model at its core and react web UI which helps Network planners view all Inventory related KPIs and daily stock levels. It recommends Material Order Dates and Quantities based on demand predictions, lead time, existing inventory levels, and returns. It also alerts users about under-stocks and overstocks to take appropriate action.

Benefits

- The major benefit of this application was Data-driven decision-making for Material Purchase quantities and timelines ensuring optimal CAPEX spending. The benefits of using inventory management techniques are that they simplify the process of maintaining your inventory and saving your time and revenue. Reduce overstocking and proactive action to prevent understocking through efficient monitoring and recommendations resulting in Just In Time Inventory.

Network

Capacity Planing

Our client had thousands of servers spread across the globe carrying internet traffic. The main challenge was managing these servers at optimal utilization.

Vendor Contract Analytics

Our client had thousands of contract documents scanned and stored as pdf documents. Manually scouring through these documents...

Automated image quality check

Our client receives a large number of crowd sourced images. They receive many pictures which are blurry and some of the images...